Hemp Materials: Why Should You Use Hempcrete As a Building Material?

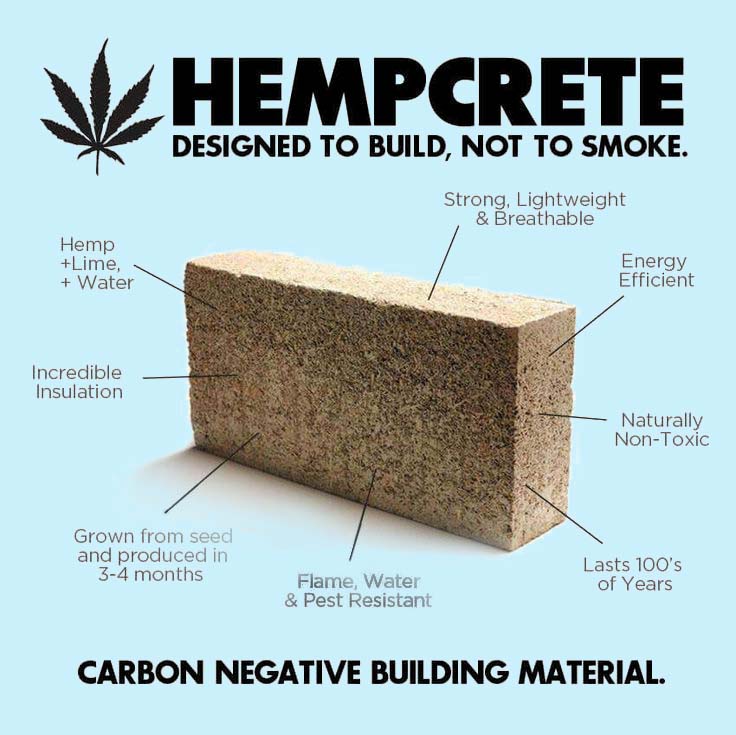

Hemp materials are in abundance, however you may not have heard of all of them. Hempcrete is one of the most amazing building products made from industrial hemp. All it is, is hemp hurds, or the center of the stalk, water, and lime — powdered limestone. Mix these into a slurry and form it in to the wall of a building and over time, the chemical reactions with petrify the hemp. The lime will turn back into stone.

Since the hempcrete eventually turns to petrified rock, the hempcrete bricks will last for hundreds of years.

Hemp Materials: Benefits of Hempcrete

1Non-Toxic

2No Off-Gassing

3No Solvents

4Mold Resistance

5High Vapor Permeability

6Humidity Control

Why Hempcrete Instead of Concrete?

Modern day building materials are either mined form the earth or harvested from centuries old forests. Hemp crops can be harvested annually in perpetuity. One acre of hemp provides as much paper as 4.1 acres of trees. Considering the trees take decades to grow and hemp takes about 4 months, the advantages become clear. In some areas of the US, you can grow more than one crop of hemp a year.

One ton of manufactured cement (1400-1450°C) releases 850kg of carbon dioxide into the atmosphere!

This is a consequence of the chemical reaction and can not be reduced by energy saving. The use of lime instead of cement will save approximately 80% of the CO2 release compared to ordinary cement. One single residence will save between 5,000 and 10,000lbs of CO2 emissions.

Hemp Materials in Construction

The one drawback is that hempcrete takes a long time to cure, so it’s not good to use for load bearing walls. To make up for this, companies started making hempcrete bricks. There are quite a few companies that make hempcrete bricks. They manufacture them in a way that it takes a lot less time to cure than just putting the slurry into the wall cavity.

There are various ways these bricks are made, one method is to put the slurry into wooden forms and leave to dry. Another method is to press into machines and forma brick, then leave to cure. Some companies put supporting structures such as 2×2’s in the bricks so you can use them for load bearing walls immediately. After they are suitably cured, they are able to be stacked just like normal bricks. They are usually a few inches thicker than regular cinderblocks and are a lot lighter. With these bricks, the need for a wooden frame is practically zero, and since they eventually turn to petrified rock they will last for hundreds of years.

Benefits of Hempcrete Continued:

1Durable

2Sustainable

3Carbon Sequestration

4Fire & Pest Resistant

5Humidity Regulation

6Great Insulator

Hemp Industrial Materials

Learn what all hemp industrial materials and products are out there. Utilize their numerous benefits why staying ethical and using organic, healthy materials.